Intelligent feeding for intelligent processes

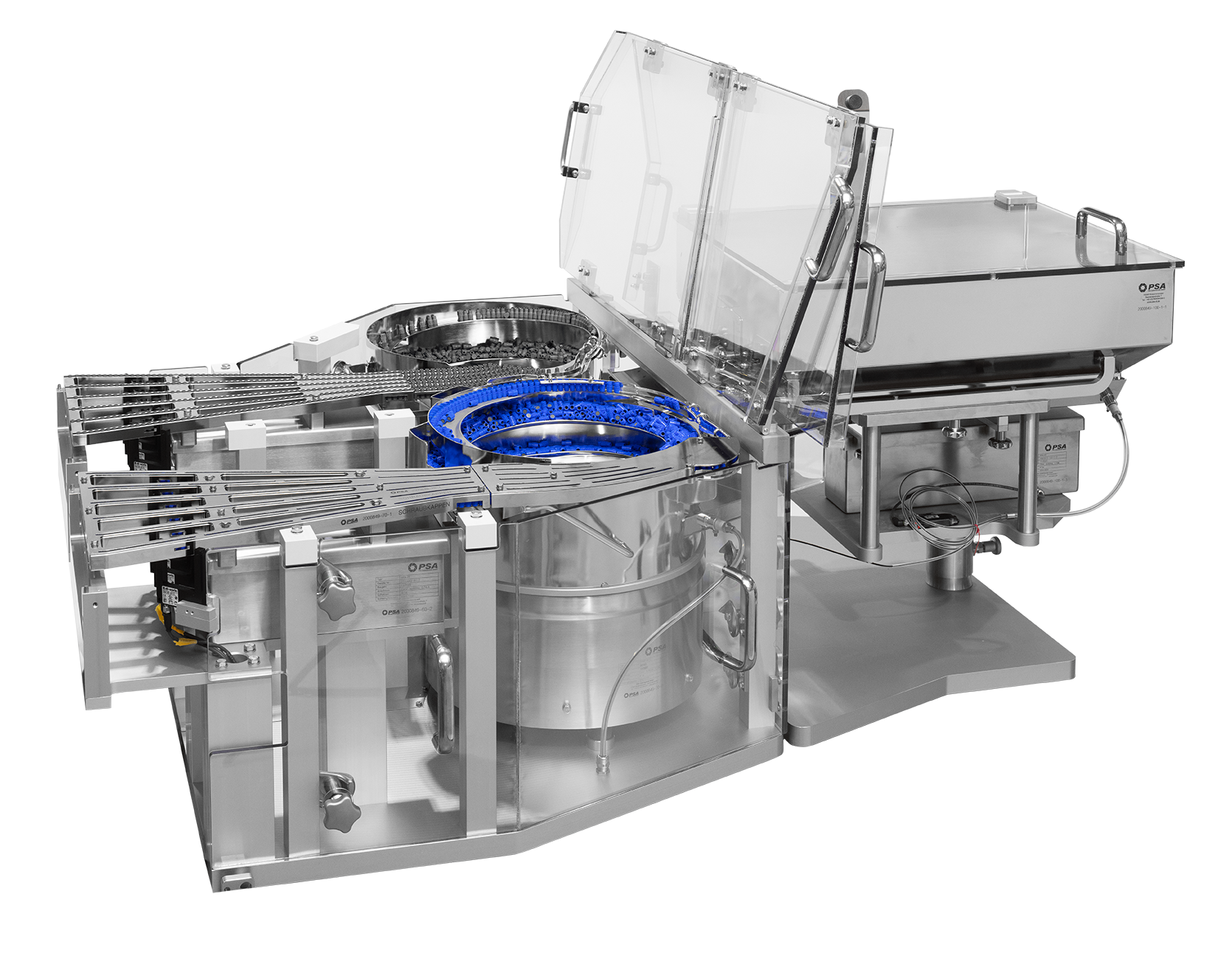

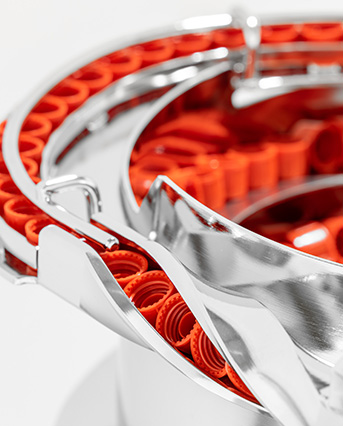

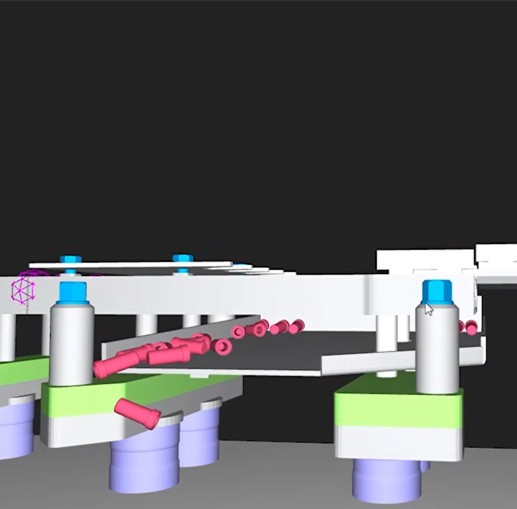

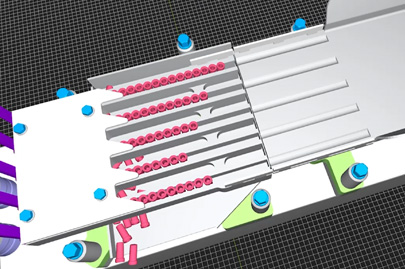

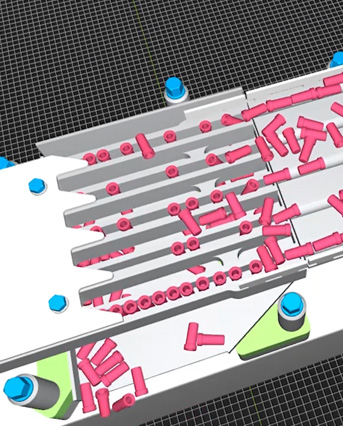

As a mechanical engineering company, we develop and manufacture sorting and feeding systems, individually tailored to the requirements of our customers.

Our competence focuses on the development and realisation of highly efficient, perfectly processed and thus sterilisable components and complete systems which are mainly used in the aseptic sector - for medicinal products, solutions and suspensions.

With the help of our feeding technology, for example, closure parts such as flip-off caps, rubber or piston stoppers for pharmaceutical containers, already completed single or multi-dose containers such as syringes can be correctly positioned and fed, so products can be processed seamlessly and smoothly. Terms such as "GMP" and "Annex 1" are highly relevant to us on a daily basis, because our core competence lies predominantly in the pharmaceutical sector.

Jobs and career

To all technology freaks who like to get stuck in: here you'll find great jobs and the best colleagues!

Attention: Our team spirit is contagious! Let us inspire you and develop your future with us.

Highest quality, expertise and innovation make us market leaders and increase the success of our customers.

Current exhibition